Accelerator ZDBC(BZ) Green

Accelerator ZDBC(BZ) Green

|

Product Name

|

ZDBC (BZ) Green

|

|

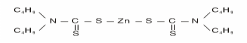

Chemical Name

|

Zinc dibutyldithiocarbamate

|

|

Molecular Formula

|

|

|

CAS No.

|

136-23-2

|

|

Molecular Weight

|

474.12

|

|

Specifications

|

|

Item

|

Standards

|

|

Product Form

|

Powder

|

dust-free powder

|

|

Appearance

|

White Powder

|

|

Initial Melting Point ℃ (≥)

|

104.0

|

102.0

|

|

Loss on Drying % (≤)

|

0.4

|

0.4

|

|

Zinc Content %

|

15.5-17.5

|

15.5-17.5

|

|

Density,g/cm3

|

1.24

|

1.24

|

|

Residue on 63μm Sieve % (≤)

|

0.5

|

0.5

|

|

Residue on 150μm Sieve % (≤)

|

0.1

|

0.1

|

|

Additive, %

|

|

|

|

Application

|

|

Vulcanization speed

|

Super Speed Class

|

|

Application

|

◆ RXX ZDBC is used as secondary ultra accelerator for thiazole and sulfenamide cure systems in general purpose polymers (NR, SBR, IIR, E-PDM). It can be used as a primary accelerator in specialty applications as well as in latex.

◆ In latex applications RXX ZDBC is mainly used in transparent goods and in prevulcanized latex.

◆ An additional application is as an antioxidant in adhesive systems.

◆ RXX ZDBC gives faster cures than RXX ZDEC or RXX ZDMC.

◆ General dosage: 0.5—2 phr.

|

|

Package

|

|

Kraft paper bag

|

25 kg

|

|

Validity

|

24 months

|

|

EINECS No

|

238-778-0

|

|

Executive standard

|

Q/ZYCH6-2013

|

|

name

|

ZDBC(BZ)-80

|

|

Carrier

|

SBR+TPR

|

|

Chemical Composition

|

Zinc dibutyl dithiocarbamate

|

|

Active Content %

|

80

|

|

Color

|

Grey-white granules

|

|

Mooney Viscosity ML1+4 50℃ ≤

|

70

|

|

Mesh

|

100

|

|

Density

|

1.08

|

|

ZDBC(BZ)-80

|

Pre-Dispersed Polymer Bound Chemicals

|

|

function

|

Vulcanizing Agent

|

|

composition

|

A homegeneous mixture of zinc di-butyl-dithiocarbamate and polymeric binder at 80/20 ratio

|

|

Density(g/cm3)

|

Approx 1.08

|

|

|

|

|

Application Notes

|

|

Use

|

ZDBC-80 is a ultra-accelerator for natural rubber and synthetic rubber.In case of blooming,it always use together with other dithiocarbamates and keep the dosage under 1 phr.It's also a good activator for thiazoles accelerators and very suitable for high-clarity products

|

|

Dosage

|

0.1 - 2.0phr

|

|

Packaging

|

25 kgs in carton box with polyethylene bag liner

|

|

Storage

|

Keep cool (below 25℃) and dry in original package.24 months from production date

|